Ion Implantation Services

We offer a wide range of services, from R&D support to small-batch production. In addition to confidentiality, our strengths lie in our ability to provide quick and flexible solutions within quick delivery times.

Ion implantation is a process that does not alter colouration and shape and cannot be observed by the naked eye. We value trust and will consistently provide the most suitable services to meet or customers’ expectations. Years of experience and achievements are a testament to that.

Ion Implantation of ITC

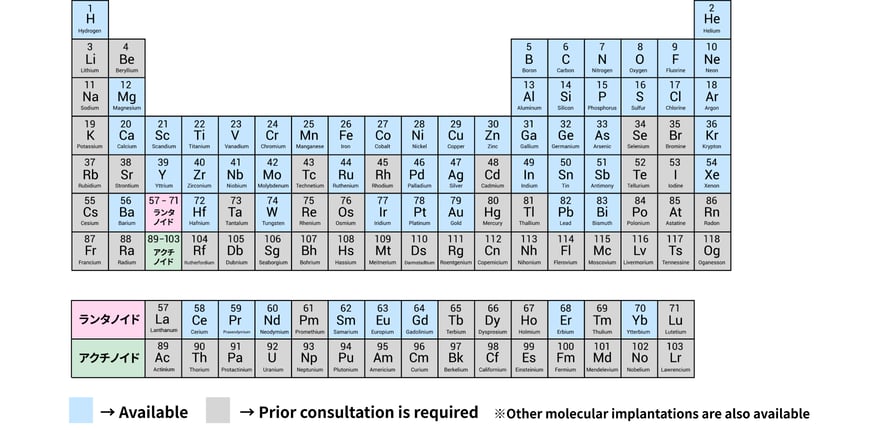

Handling Over 60 Different Ion Species

We can handle over 60 different ion species including H, B, P, As used in Si substrates, N, Al used in SiC substrates, and Fe, Mg, Si used in GaN substrates.

Handling a Wide Range of Samples (Substrates)

We can handle a wide range of sizes, from small pieces to large-diameter substrates, and support various types including silicon substrates, SiC, GaN, Ga2O3, and compound semiconductor substrates. Of course, we also handle a wide range of other materials.

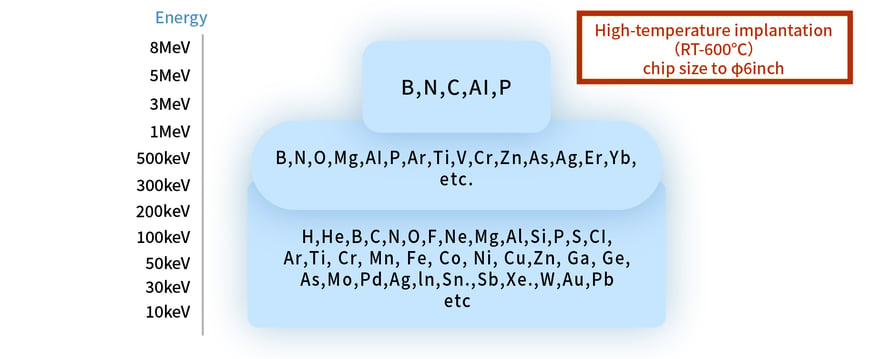

High-temperature Ion implantation

We can handle high-temperature ion implantation that is expected to alleviate damage. Our strength is the wide range of ion implantation temperatures, from room temperature to 600°C. We can handle samples ranging from small pieces to 6-inch wafers (150 mm), even at 600℃.

High acceleration energy implantation

We can implant ion at high acceleration implantation. We can handle a range between 5 keV and 8 MeV. ITC’s strength lies in its ability to work across a wide energy range.

Implanted Ion Species

Not only B, P and As, but also more than 60 other types of atoms, such as Al and N, can be implanted.

Acceleration Energy

We can handle a wide range of energy levels:

Medium current equipment: 5-750 keV (With triple-charged ions. Depending on the ion species. Please contact us in advance)

High-energy equipment: up to 8 MeV

Regarding Consignment

We offer a diverse service lineup including ion implantation, high-temperature ion implantation, high-temperature rapid annealing, carbon cap film, and more.

Furthermore, the above processes can be bulk consigned. For more information, please contact us.

Principles of the Ion Implantation Equipment

-

01

Ion Source

Generating ions of the target element

-

02

Mass Spectrometer

Separating multiple types of ions according to their mass and charge

-

03

Analysis Slit

Selecting only the required ions and introducing them into the acceleration column

-

04

Acceleration Column

Accelerating ions to a predetermined energy level

-

05

Q Lens

Shaping beams

-

06

Scanner

Scanning ion beams in the X and Y directions

-

07

End Station

Ion implanting into samples (substrates)

Major Clients

And More

Service Initiation Procedure

-

01

Inquiry

Please contact us through the inquiry on our website. -

02

Consultation

Both online and offline support are available.

-

03

Quotation

We will provide a quotation via email or online.

-

04

Contract Decision

We will adjust the delivery schedule to meet your desired timeframe.

-

05

Specification Finalization

We will compile the specifications (application form) to finalize the terms.

-

06

Sample Provision

Generally, we accept sample provision by express courier services from customers. (Please let us know if you have other preferences).

-

07

Ion Implantation Work

We will reserve the equipment schedule and proceed with work.

-

08

Shipment

We will send the sample by express courier services together with the invoice, work data and delivery documents.