Carbon Cap Film

For SiC semiconductors, high-temperature annealing is essential for dopant activation. However, due to the elevated annealing temperature, surface protection with a cap film before annealing becomes necessary. We not only address the need for high-temperature annealing but also address the need for carbon cap film deposition.

Effects of Carbon Cap Film

The carbon cap film helps reduce surface roughening after high-temperature annealing.

Supported Processing Conditions

Method |

A film is deposited on the surface by an acetylene reaction (C2H2). |

|---|---|

Film Type |

DLC film |

Film Thickness |

Standard: 70nm (other thickness is possible) |

Film Formation Rate |

Standard: about 7nm/min. |

Supported Size |

5 mm square to 6-inch wafer |

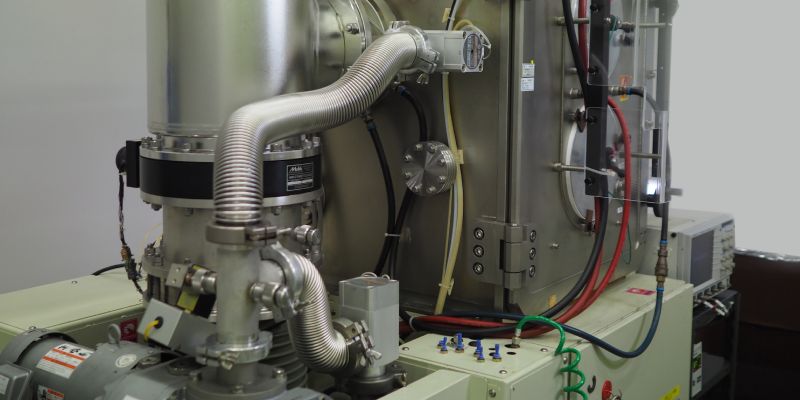

Configuration Diagram

Film Formation Equipment

Technical Brochure Download

Summarized information about our film formation and heat treatment equipment

Download here "Film Formation and Heat Treatment Equipment Lineup Technical Brochure

Disclaimer

While every effort has been made to ensure that information on our website is as accurate as possible, we do not guarantee the accuracy and completeness of the content. Please note that the content and URLs of our website may be updated, added, changed or discontinued, or deleted without prior notice. Including the reasons mentioned above, the company will not be liable for any damage or loss incurred based on the provided information. The author’s affiliation is as of the time of writing.

The copyright of our website, its contents and individual articles belong to our company.

- TOP >

- Services >

- Ion Implantation Services >

- Carbon Cap Film